Cashewnut (Anacardium occidentale L.)

Anacardiaceae |

|

|

|

| Cashew nuts hanging on a tree |

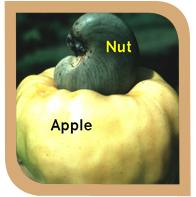

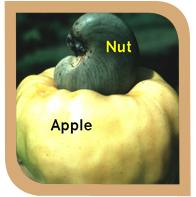

Cashew apple and nut |

Production Centers of Cashew in India |

|

Varieties: |

(Click on the variety name to see the detailed information) |

| |

Tamil Nadu Varieties |

: |

VRI-1,VRI-2,VRI-3,VRI-4 , VRI (CW) H1 |

| |

Kerala Varieties |

: |

Akshaya ,Amrutha ,Anagha ,Anakkayam-1 ,Dhana ,Dharasree ,

|

| |

|

|

K-22-1,Kanaka ,Madakkathara -1 ,Madakkathara-2,Priyanka ,Sulabha , Mrudula, Poornima, Sree, KAU Nihara |

| |

Andhra Pradesh Varieties |

: |

BPP-1,BPP-2,BPP-3,BPP-4,BPP-5,BPP-6,BPP-8, BPP -10,BPP -11 |

| |

Karnataka Varieties |

: |

Chintamani-1, Chintamani-2 NRCC-1,NRCC-2,Ullal-1,Ullal-2,Ullal-3,Ullal-4,UN-50, H-130, Bhaskara , Nethra Vaman |

| |

Maharastra |

: |

Vengurla-1,Vengurla-2,Vengurla-3,Vengurla-4,Vengurla-5,Vengurla-6,Vengurla-7 , Vengurla-8 |

| |

Goa |

: |

Goa-1 , Goa 2 |

| |

Orissa |

: |

Bhubaneswar-1, Jagannath , Balabhadra , |

| |

West Bengal |

: |

Jhargram-1, Jhargram-2 |

|

Soil and climate

Soil and climate

It grows up well in all soils. Red sandy loam is best suited. Plains as well as hill slopes upto 600 - 700 feet elevation are suitable.

Season

June – December is optimum for cultivation.

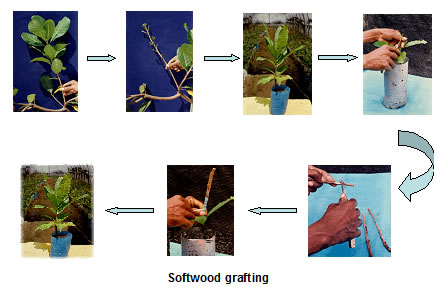

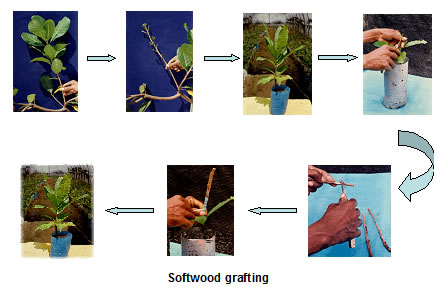

Propagation

Mainly propagated by soft wood grafting, air layering and epicotyl grafting

Requirement of plants

About 200 plants/ha can be planted.

Preparation of field

Pits of 45 cm x 45 cm x 45 cm size are dug and filled up with a mixture of soil + 10 kg FYM + one kg neem cake

Spacing

A spacing of 7 m either way is adopted

High Density Planting

Spacing of 5 x 4 m accommodating 500 plants per hectare is recommended prune the interlocking branches during the July-August to maintain the frame.

Manuring (per tree)

| Manures and fertilizers |

I year old |

II year old |

III year old |

IV year old |

V year onwards |

| FYM or compost (kg) |

10 |

20 |

20 |

30 |

50 |

| N (g) |

70 |

140 |

210 |

280 |

500 |

| P (g) |

40 |

80 |

120 |

160 |

200 |

| K (g) |

60 |

120 |

180 |

240 |

300 |

Fertilizer application may be done during November - December in the East Coast areas. Wherever possible the fertilizer can be applied in 2 equal split doses during June-July and October-November periods under east coast area, a fertilizer schedule of 1000:125:250 g NPK/tree is recommended tree.

Intercropping

Plough the interspaces after the receipt of rain and raise either groundnut or pulses or minor millets till the trees reach bearing age.

Irrigation: Normally grown as a rainfed crop. Irrigation once in a west from flinching to fruit maturity stage is good to increase the yield.

Training and pruning

Develop the trunk to a height of 1 m by removing low lying branches. The dried twigs and branches should be removed every year.

Rejuvenation of old cashew orchard by top working

Old and senile cashew orchards with poor yielder are cut down leaving a stump of 1 – 3 m height from the ground level. The emerging new sprouts are used as rootstock for epicotyl grafting. Suitable scions are collected and grafted on to the new sprouts.

Plant protection

Pests

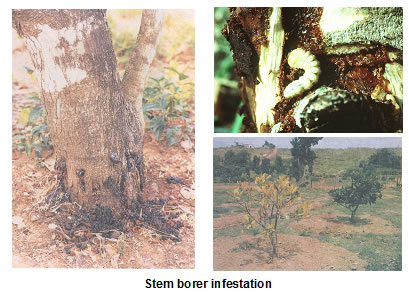

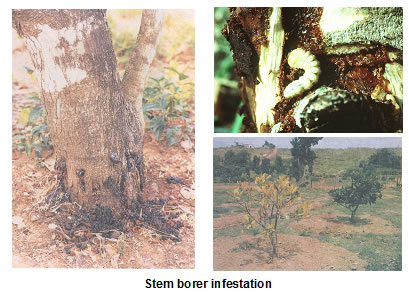

Stem borer

1. Collection and destruction of affected shoots

2. Swabbing the bark of exposed roots and shoots with Carbaryl 50 WP 2 g/lit. Twice a year before the onset of South West Monsoon (March – April) and after cessation of monsoon (November) painting of coal tar + kerosene mixture (1:2) or swabbing with a suspension of Carbaryl 50 WP (4 g/lit) can be done up to one metre length in the exposed trunk region after shaving the bark or swab the tree trunk with neem oil 5% thrice during JanuaryFebruary, May-June, and September-October..

3. Root feeding with of water kept in a polythene bag on one side of the tree and keep the same amount on the other side of the tree (Total 20 ml/tree) divided into two equal halves will give protection when there is moderate incidence.

4. Remove grubs from early stage infested trees and drench the damage portion with Chlorpyriphos 0.2% @ 10 ml/lit or Neem Oil 5%.

Tea mosquito bug

-

Spray application of phosalone 35 EC@ 2.0 ml, followed by carbaryl 50WP @ 2g/l at vegetative flush stage, panicle initiation stage and nut formation stage respectively are recommended for the management of tea mosquito bug.

-

Spray schedule involving three rounds of spray viz., first spraying with Profenophos (0.05%) at flushing stage, second spraying with Chlorpyriphos (0.05%) at flowering and third spraying with Carbaryl (0.1%) at fruit set stage is most effective.

Shoot caterpillars

Shoot caterpillar can be controlled by spraying Profemophos 50 EC @ 2 ml/lit.

Root borer

Root borer can be controlled by pouring tree in the bore holes (Insecticide 5 ml + 5 ml water).

Leaf miner

1. Collect and destroy the damaged plant parts

2. Spray NSKE 5% two rounds, first at new flush formation, second at flower formation

Diseases

Die back or Pink disease

Prune the affected shoots just below the affected portion and apply Bordeaux paste. Spray 1 % Bordeaux mixture or any copper fungicide like Blitox or Fytolan 0.25 % twice i.e. in May - June and again in October as a prophylactic measure.

Anthracnose

1. Remove the affected portions of plant/branches

2. Spray 1 % of Bordeaux mixture + Ferrous sulphate at the time of flush initiation

Harvest

The plant starts yielding 3rd year onwards. The peak picking months are March and May. Good nuts are grey green, smooth and well filled. After picking, the nuts are separated from the apple and dried in the sun for two to three days to bring down the moisture content to 10 to 12 %. Properly dried nuts are packed in alkathene bags. This will keep for 6 months.

Yield

About 3 - 4 kg/tree/year can be obtained.

Cashew Processing

Processing of cashew is defined as the recovery of edible meat portion- the kernel from raw nuts, by manual or mechanical means. In India, the processing is by manual means. It consists of;

1. Roasting 2. Shelling 3. Peeling 4.Sweating 5. Grading 6.Packing

Roasting is designed to make shell brittle.

a. Open Pan Roasting

The earliest process was the pan roasting wherein the nuts are heated on a metal pan over an open fire. Due to the heat and slight charring the shells become brittle. The pan roasting is not followed in organized sectors of industries. The two important methods of processing now adopted are; a. Drum roasting and b. Oil bath roasting.

b. Drum roasting

The nuts are fed into a rotating hot drum, which ignites the shell portion of the nut. The drum maintains its temperature because of the oil oozing out of the nuts. The drum is kept in rotation by hand for about 2-4 minutes. The roasted nuts which are still burning are covered with wood ash to absorb the oil on the surface. The rate of shelling and the outturn of whole kernels are very high in this method. However, the main disadvantage is the loss of CSNL which has a very high export potential. In addition there will be considerable heat and acrid fumes in the vicinity of this operation.

c. Oil bath roasting

In this method, the nuts are held in wire trays and are passed through a bath of cashew shell oil maintained at a temperature of 200-202oC for a period of three minutes whereby the shell oil is received from the shells to maximum possible extent. The vessel is embedded in brick work and heated by a furnace which use spent shell as fuel. During roasting, the shell gets heated and cell wall gets separated releasing oil into bath. As the level rises the oil is recovered by continuous overflow arrangement. The roasted nuts are then converted into a centrifuge. The residual oil adhering to the surface of nuts is removed by centrifuging. The roasted nuts are mixed with wood ash and sent for shelling.

In Panruti (Tamilnadu) the conventional roasting is completely avoided. The raw nuts are exposed to the intense sun that is prevalent in that region. The well dried nuts are hand shelled. Here also the CSNL is completely recovered.

Moisture Conditioning or Humidifying:

A slight under roasting or over roasting adversely affects the quality of the kernels. This is achieved by a moisture step preceding the roasting. The raw nuts are sprinkled with water and allowed to remain in moist condition for about 24-48 hours. This step is known as conditioning. The optimum moisture level at the end of roasting is reported to be 15-20%. Two important points to betaken care of during conditioning are;

- The water should not seep through the brown testa.

- The water should be free from iron contaminations.

Iron contamination in the water can interact with polyphenolic materials of testa and the resultant bluish black complex may give patches on white kernel.

2. Shelling

After roasting, shelling is done by labour. Each nut is placed edgewise and cracked open with a light wooden mallet and the kernel extracted with or without wire prong. Care has to be taken that the inner kernel is intact and not broken into bits. After kernels are removed from the shells they have to be dried to reduce the moisture to loosen the adhering testa.

3. Peeling

Peeling is the removal of testa from the kernels. This is done with help of safety pin or small hand knife. Peeling is made easier when the kernels are subjected to a heat treatment for about 4 hrs in a drying chamber.

4. Sweating

After peeling, the kernels are spread out indoors on cement flooring so that they may absorb some moisture and become less brittle. This prevents the tendency to break easily during grading.

5. Grading

The next stage in the processing is the grading of kernels on the basis of specifications for exportable grades. There are 25 exportable grades of cashew kernels. The kernels are stored into wholes, splits and Broken primarily on the basis of visual characteristics. The wholes are again size-graded on the basis of the number of kernels per 1Ib. The entire grading operation is done manually. However for size-grading mechanical operation is also practiced.

Specification for cashew kernels

| Grade designation |

Number of kernels per lb |

Grade designation |

Number of kernels per lb |

| W 180 |

375 to 395 |

W 320 |

660 to 705 |

| W 210 |

440 to 465 |

W 400 |

770 to 880 |

| W 240 |

485 to 530 |

W 450 |

880 to 990 |

| W 280 |

575 to 620 |

W 500 |

990 to 1100 |

General Characteristics

Cashew kernels shall have been obtained through shelling and peeling cashew nuts, shall have the characteristic shape, shall be white or pale ivory or light ash in colour, reasonably dry, and free from insect damage, damaged kernels and black or brown spots. They shall be completely free from rancid kernels. The kernels shall be completely free from testa.

Grade designations and their trade names:

| Grade designation |

Trade names |

Grade designation |

Trade Names |

| SW |

Scorched Wholes |

SB |

Scorched Butts |

| SSW or SW IA |

Scorched Wholes Seconds or Scorched Wholes IA |

SS |

Scorched Splits |

| DW |

Dessert Wholes |

SP |

Scorched Pieces |

| B |

Splits |

SSP |

Scorched Small Pieces |

| S |

Splits |

SPS |

Scorched Pieces Second |

| LWP |

Large white pieces |

DSP |

Desert Small Pieces |

| SWP |

Small white pieces |

DB |

Desert butts |

| BB |

Baby bits |

DS |

Desert Splits |

6. Packing

Final operation is packing in 10 kg capacity tins, which are subsequently evacuated and filled with carbon dioxide. In some parts to overcome the possible over-drying a re-humidification step is introduced before packing. The practice of filling with an inert gas is mainly to combat infestation during transit. It may be pointed out that with high quality nut, free from infestation, storing with or without carbon dioxide makes very little difference particularly with reference to rancidity. The importance of inert gas appears to be more for circumventing a possible insect attack from an occasional insect egg entering the tin while packing.

Nitrogen can also do the same function. However, carbon dioxide being a heavier gas is more convenient for handling. Contention that absorption of carbon dioxide makes the kernel tastier does not have much truth. In any case the processed kernels are rarely consumed without a subsequent heat processing in the form of roasting frying and/or baking.

By products of cashew

After the processing of the shell and other left outs are used making some other products. The major bye products of cashew processing are:

1. Cashew Nut Shell Liquid 2. Shell charcoal

1. Cashew Nut Shell Liquid

The pericarp of the nut consists of a coriacious epicarp, spongy mesocarp and stony endocarp. The kernel covered with testa membrane is contained in a shell 1/8 inch thick. The mesocarp consists of a honeycomb network of cells containing a viscous liquid called cashew nut shell liquid (CSNL), which provides a natural protection to the kernel against insects.

CSNL is a valuable raw material for a number of polymer based industries like paints and varnishes, resins, industrial and decorative laminates, brake linings and rubber compounding resins. CNSL is traditionally obtained as a byproduct during the isolation of kernel. The major constituent of shell oil is cardanol and anacardic acid of which cardanol is separately extracted and used in many industries. The shell oil was used as a preservative for boats and nets and to protect wood from termites. It is now largely exported and used in the manufacture of plastics, indelible inks, water proofing composition and other industrial products.

Extraction of CNSL

The extraction of CNSL involves various methods viz. hot oil bath, expellers, kiln method, solvent extraction etc, the most common method being hot oil bath. In this method the raw nuts are passed through a bath of CNSL itself by which the CNSL is extracted. This method extracts only 50% of liquid contained in nuts. Then through expellers about 90% of liquid can be extracted.

Cashew shell charcoal

The remains of shell after the extraction of CSNL is called shell charcoal. This is used as a fuel. The shell charcoal is used in processing of cashew for drying after shelling.

Market information

| Growing Districts |

Cuddalore, Tirunelveli |

| Major markets in Tamil Nadu |

Jayankondam, Vridhachalam, Panruti |

| Grade specification |

White/ Pieces, splits, butts |

|